We are Manufacturer, Supplier, Exporter of Screw Conveyor Coolers and our setup is situated in Sangli, Maharashtra, India.

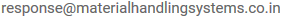

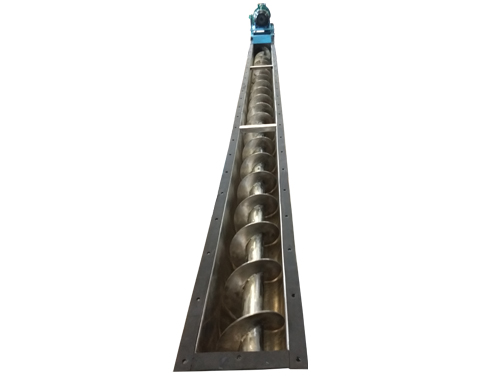

Screw Conveyor Coolers are a type of industrial equipment used in various processes, particularly in bulk material handling and processing industries. They are specifically designed to cool materials such as powders, granules, flakes, or pellets by using a rotating screw inside a trough or tube.

Here's how they typically work :

- 1. Material Input : The hot or warm material enters the screw conveyor cooler through a hopper or feeder at one end of the equipment.

- 2. Conveying : A screw, usually made of metal, rotates inside the trough or tube. As it rotates, it pushes the material along the length of the conveyor.

- 3. Cooling : External cooling mechanisms, such as ambient air or water jackets surrounding the trough or tube, help dissipate heat from the material as it moves along the conveyor. Sometimes, additional cooling elements, like fans or sprayers, may be incorporated into the design to enhance the cooling process.

- 4. Discharge : The cooled material exits the screw conveyor cooler at the other end, ready for further processing, packaging, or storage.

These coolers are versatile and can be customized to suit different materials and processing requirements. They are commonly used in industries such as food processing (for cooling grains, cereals, or spices), chemical processing (for cooling chemicals or fertilizers), and manufacturing (for cooling plastics or rubber compounds), among others.

The design and specifications of a screw conveyor cooler depend on factors such as the material being cooled, required throughput, cooling temperature, and environmental conditions. They are often chosen for their efficiency, reliability, and ability to handle a wide range of materials.