We are Manufacturer, Supplier, Exporter of Ribbon Blenders and our setup is situated in Sangli, Maharashtra, India.

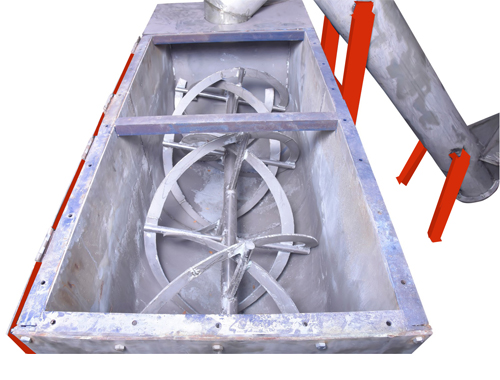

Ribbon Blenders consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator.

A ribbon agitator consists of a set of inner and outer helical agitators.

The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction to create uniform blending.

Efficiency of Ribbon blenders is measured by CV ( Coefficient of variation ).

As per the standard it must be below 5 to call it uniform Mixing.

We strictly adhere.

We have different range of ribbon blenders.

Our Ribbon Blender mixers are widely used in chemicals & cosmetics Industry, In Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, Mineral Mixtures etc.

Ribbon blenders are industrial mixing machines used in various sectors for blending dry powders, granules, and other solid materials. They are characterized by their unique ribbon-shaped agitator blades that rotate within a cylindrical container.

Here are some key features and applications of ribbon blenders :

- 1. Mixing Principle : 1.Ribbon blenders work on the principle of a ribbon-like agitator rotating within a U-shaped trough. The agitator consists of inner and outer helical ribbons that move materials in opposing directions, ensuring thorough mixing.

- 2. Versatility : Ribbon blenders are versatile and can handle a wide range of materials, including powders, granules, pellets, and cohesive materials. They are commonly used in industries such as food processing, pharmaceuticals, chemicals, plastics, and cosmetics.

- 3. Gentle Mixing : The gentle mixing action of ribbon blenders makes them suitable for blending fragile materials or ingredients that require minimal degradation or alteration during mixing.

- 4. Uniform Mixing : The design of ribbon blenders promotes uniform blending by continuously lifting and folding materials, ensuring consistent mixing throughout the batch.

- 5. Customizable Options : Ribbon blenders come in various sizes and configurations to suit different production needs. They can be equipped with features such as jackets for heating or cooling, vacuum or pressure capabilities, and different types of discharge options.

- 6. Easy to Clean and Maintain : Many ribbon blenders are designed for easy cleaning and maintenance, with features such as removable ribbon assemblies, access doors, and sanitary finishes to meet hygiene standards in industries like food and pharmaceuticals.

- 7. Batch or Continuous Operation : Ribbon blenders can operate in batch mode, where materials are loaded, mixed, and discharged in batches, or in continuous mode for applications requiring a constant flow of blended materials.

- 8. Cost-Effective Solution : Ribbon blenders offer a cost-effective solution for blending applications compared to other mixing equipment like tumble blenders or high-shear mixers, especially for large-volume production.

Overall, ribbon blenders play a crucial role in various industries by providing efficient and reliable mixing solutions for a wide range of materials.

En masse conveyors, also known as en masse drag conveyors or simply en masse conveyors, are a type of mechanical conveying Systems used to move bulk materials such as grains, powders, and pellets horizontally, vertically, or at an incline.