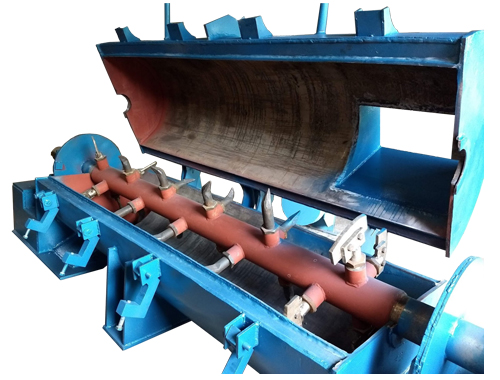

We are Manufacturer, Supplier, Exporter of High Speed Shear Mixers and our setup is situated in Sangli, Maharashtra, India.

It is used to disperse and to transport one phase or ingredient ( liquid, solid, gas ) into a main continuous phase ( liquid ).

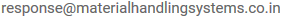

A rotor or impeller, together with a stationary component known as a stator, or an array of rotors and stators, is used either in a vessel or mixer body in which liquid is sprayed which is thoroughly mixed with the major phase of solid.

A high speed-shear mixer is used in the adhesives, chemical, cosmetic, food, pharmaceutical, and plastics industries for homogenization, particle size reduction, and dispersion.

We have different range of high speed shear mixers.

Our specialty is Shear Mixers for for laminates industries where powdered bagasse is mixed with emulsifiers.

MOC ( Material Of Construction ) is normally MS or SS304 or SS316.

High-speed shear mixers are equipment used in various industries, including pharmaceuticals, food processing, cosmetics, and chemicals. They are designed to rapidly mix, disperse, emulsify, or blend different ingredients to create homogeneous products. These mixers typically operate at high speeds, generating intense shear forces to break down particles and create a uniform mixture.

The design of high-speed shear mixers usually includes a rotating shaft with impellers or blades that rotate at high speeds within a mixing vessel. The impellers create shear forces by imparting velocity gradients and turbulence to the mixture, leading to efficient mixing and dispersion of components.

Some common types of high-speed shear mixers include :

- 1. Inline High Shear Mixers : These mixers are used for continuous processing where materials are fed into the mixer through an inlet and mixed while passing through the mixing chamber. They are often used in industries requiring continuous production and precise control over mixing parameters.

- 2. Batch High Shear Mixers : Batch mixers are designed for batch processing, where a specific quantity of materials is loaded into the mixing vessel, mixed, and then discharged after the process is complete. They are versatile and suitable for smaller-scale production or processes that require frequent product changes.

- 3. Rotor-Stator Mixers : These mixers utilize a rotor-stator configuration, where a rotating rotor with blades or teeth operates within a stationary stator. This design generates intense shear forces and is often used for emulsification and dispersion of immiscible liquids or finely dividing solid particles.

- 4. Colloid Mills : Colloid mills are specialized high-shear mixers used for the production of colloidal suspensions, emulsions, and fine dispersions. They consist of a rotor and a stator with adjustable rotor-stator gaps, allowing precise control over the shear forces and particle size reduction.

We offer High-speed shear mixers which have several advantages like efficient mixing, reduced processing time, improved product quality, and the ability to handle a wide range of viscosities and formulations.